15 Dec,2022

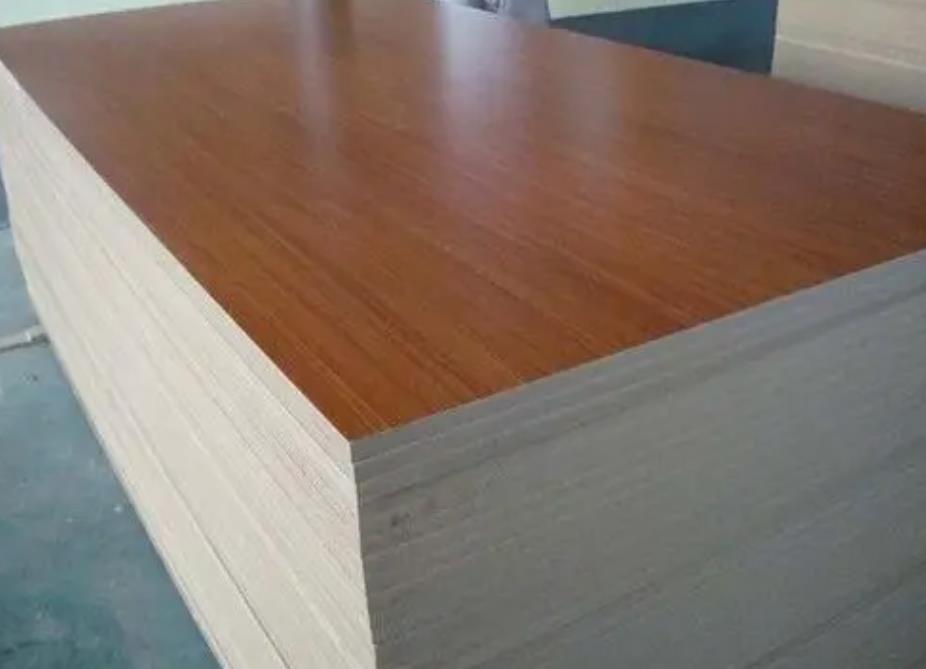

Currently, there are two kinds of plywood used in decoration,fire-resistant plywood and normal plywood. Both of them need to be painted before used in decoration, then the decoration cost is increased, and it’ll be harmful to human’s healthy for it can emits a pungent smell. Besides, there are many micropores on the surface to discount the effect of decoration.

The purpose of new production technology of decorative plywoods is to provide a type of polished plywood with smooth surface, no painting required to save cost and time, what’s more,it also will improve the decorative performance. Polishing can be divided into bright polishing and matt polishing according to different applications.

The polishing plywood are characterized in that the surface of the plywood is a layer of cured epoxy resin, it refers to common epoxy resin and flame retardant epoxy resin. The plywood baseboard is normal plywood and fire-proof plywood.

The epoxy resin can mix with pigments of different colors. The viscosity of ordinary epoxy resin and flame retardant epoxy resin is 3.2 ℃ ~ 4.5 ℃,The oxygen index O I of the r flame retardant epoxy resin is 50-58.

The steps of polishing plywood production process are as follows:

1.Coating one layer of epoxy resin which can be curable on the surface of plywood

2.Covering one layer of polyester film mound

3.Rolling Demolding

4.Demolding

The rolling pressure is 0.7 to 1 atmosphere, and the demoulding time is 40 minutes after rolling.

In order to improve the decorative effect of the plywood, and reduce the decoration cost, this technology makes the plywood and epoxy resin rolled and polished under certain conditions. It also leads to the hard protective film on the surface of the plywood and flatness of the surface. It also can isolate the fire source from the plywood if using flame-resistant epoxy.

Different color proportions of pigments added in the epoxy resin can lead to the polishing plywood in varied colors.

Compared with the prior art, the technology has the following advantages:

1. no additional painting need during decoration, and there is no environmental pollution.

2. The decorative effect is good with pretty flat surface and there is also no reflection on the surface.

3. The epoxy resin film on the surface can prevent the decaying bacteria in the air from invading the board and prolong the service life of the plate

4. Reduce the decoration time.

5. Improve the decoration quality Below in conjunction with embodiment, the present invention is further described.

Further description are made with actual case as following:

Cases

Select a piece of flame-retardant plywood, clean the surface of the dirt, put it on the interactive platform, select a flame-retardant epoxy resin solution with a viscosity of 3.8°C for coloring, and then add a catalyst and curing agent at natural temperature. The catalyst is Methylaniline styrene solution, the curing agent is cyclohexanone peroxide dibutyl phthalate paste (oxygen not more than 4.5%), pour the toned epoxy resin solution on the glue on the board, and then cover it with a matte polyester film mold, and use an air compressor to drive the rubber into the rolling on the surface, the pressure is 0.8 atmospheric pressure, so that the flame retardant epoxy resin solution on the plywood is uniform Coat evenly, remove the plywood and mylar molds at the same time, place on the bench, after 40 minutes,the mold can be removed. The oxygen index of the flame retardant epoxy resin was 55.