04 Dec,2022

The veneer dryer is ideal for drying veneers of various thickness and types. The roller type dryers have a series of steel rollers through which the veneers passes from one end to another. There are several heating sections and one or more cooling section to pull the veneers to ambient temperature and prevent reabsorption of aerial moisture.

Now let’s explore and understand its internal workings.

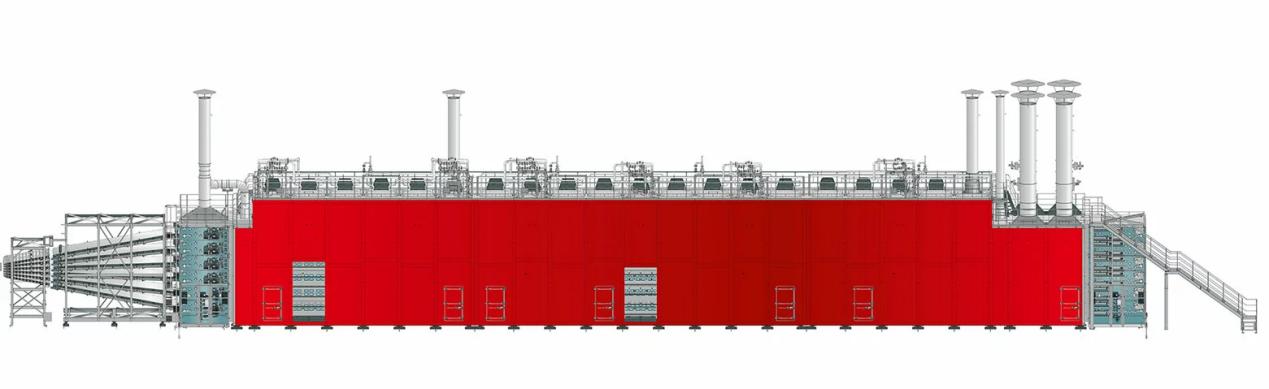

The box of dryer. the dryer can be divided into two halves. First the air space at the top with a blower assembly on one side or the blower and heating coil on the other side. Second, the conveying or drying zone at the bottom containing pairs of rollers jet box and the stand along with the sprocket to drive the rollers and convey the veneers through them.

And let’s see the airflow bar inside the dryer, the propeller pushes the air inside the dryer in a swirling motion, the guide vane converts it to a parallel flow and directs it to the heating coil, here the air get heated and under pressure, and deflection flows down to the drying zone, then it flow through the funnel stand and the jet boxes, the hot air hits the veneer from top and bottom, causing uniform and gradual moisture removing, the moisture here is sucked back by the blower and mixed with a fresh gear from the dampers below, the moisture is then removed through the dampers at the top. This applies to all the heating sections, However in the cooling section, the cooling fans sucks the atmospheric air and directly forces veneers through the jet boxes, the air is not reused now.

Let’s understand the veneer conveying path, the veneer is put on the feeding roller on each deck, keeping the wood grain perpendicular to the rollers in the heating zones. It is pressed between pairs of rollers and pushed forward, it passes between pairs of jet boxes which guide it forward without jamming it, finally it comes out of the discharge sides after passing through the cooling section, it always remains pressed between the rollers during the process hence the machine dry veneers are not very unlike sundry.