23 Nov,2022

Wood species: there are various wood species in the different countries and areas, and we separate them into two main categories: hardwood and soft according to wood density. but the wood suitable for making plywood are limited, the hardwood which suitable for making plywood include: eucalyptus, ash, maple, mahogany, oak and teak, etc, while the most common softwood used to make plywood is poplar, falcata, palm, etc, although several varieties of pine, cedar, spruce, and redwood are also used. We need to choose different woodworking machines for various wood according to their features.

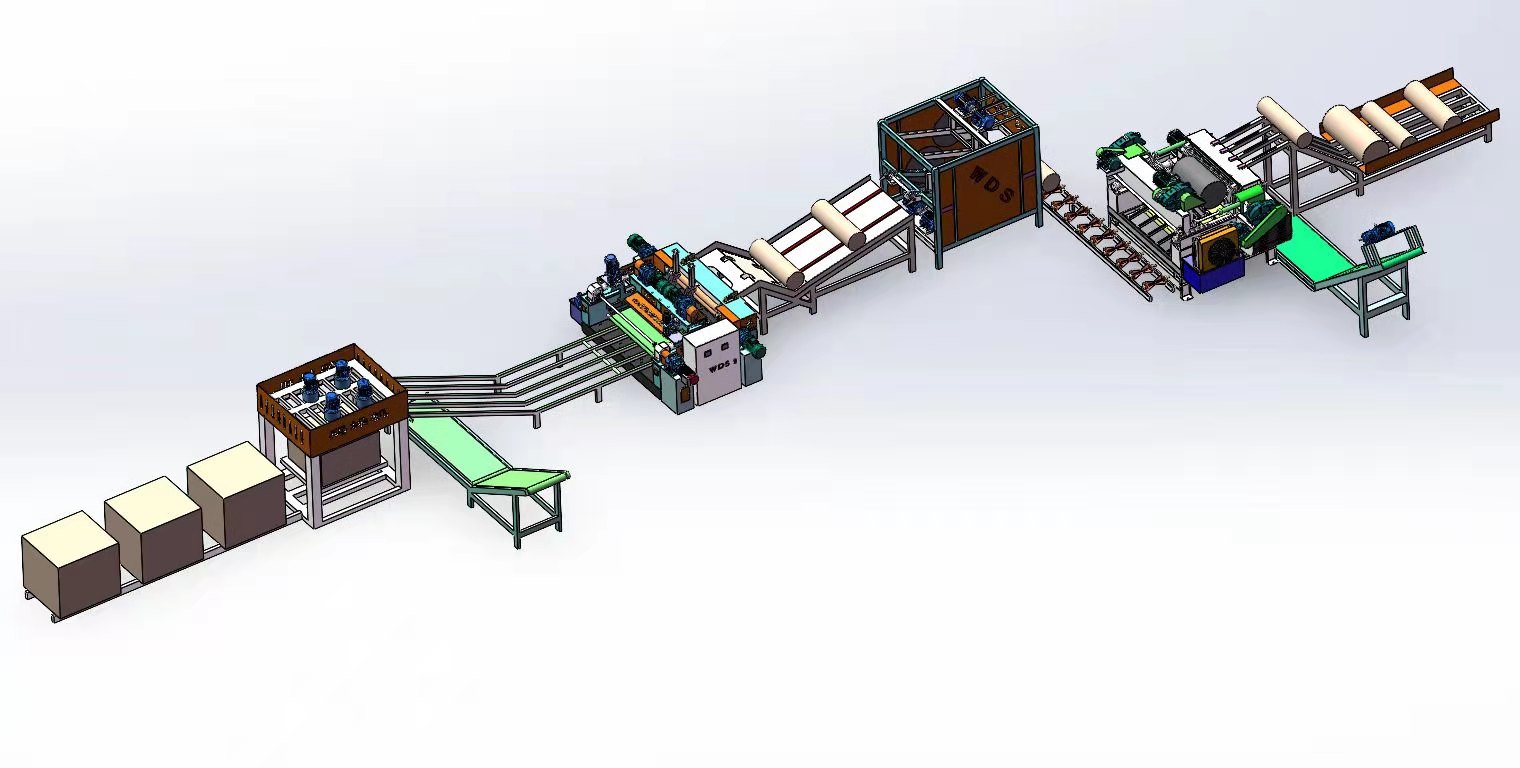

Logs debarker: Usually we choose natural wood to making plywood, the first step is to peeling the barks off the logs so that the logs are prepared to meet the high quality and safety requirements for consequence processing, such as cut, peeling. with the help of debarker machine, the barks can be removed from the logs.

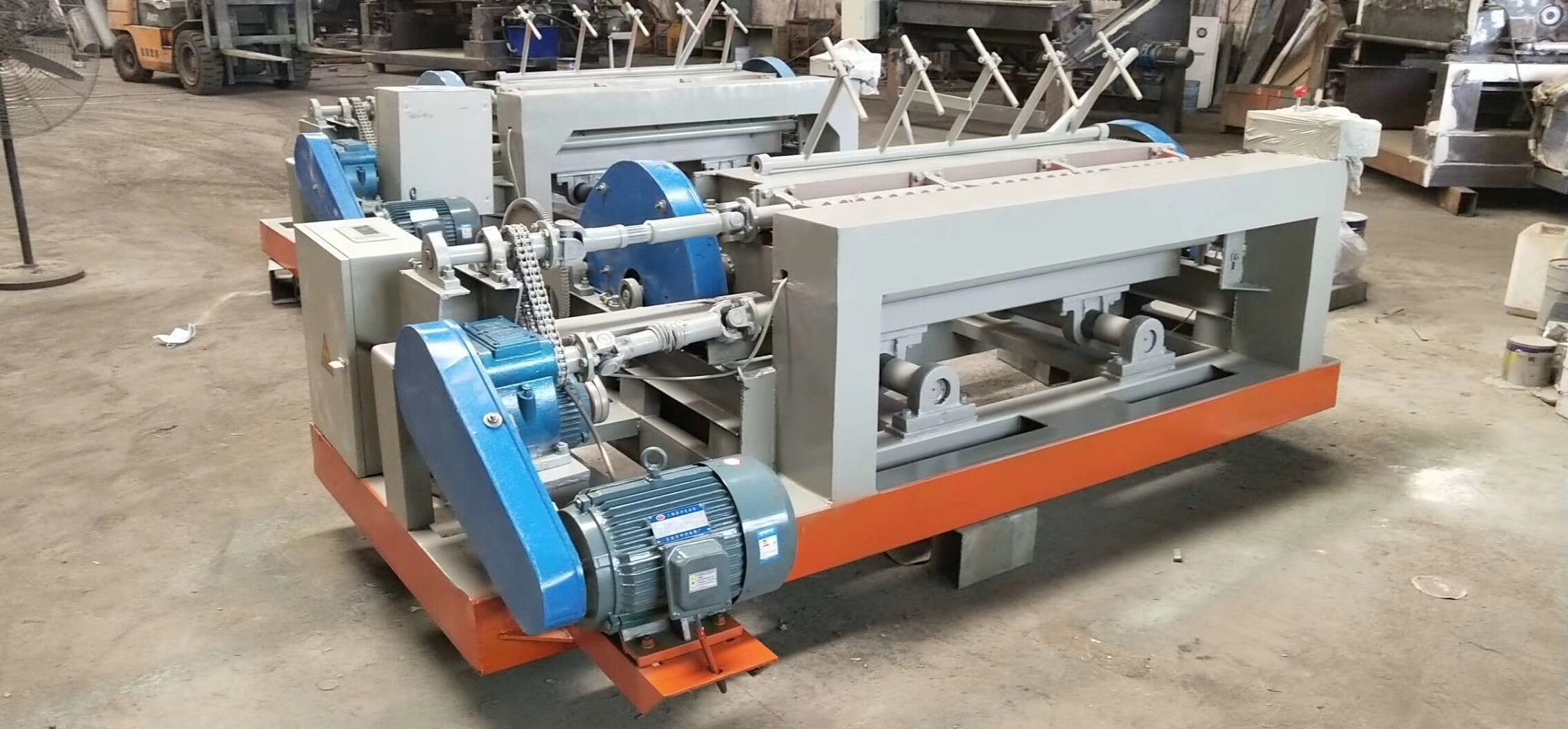

Veneer peeling: the process of logs are conducted with the help of veneer peeling machines, a knife is pushed on the entire log that continuously peels off the veneer by strong power. the thickness of veneer can be between 0.2mm to 3mm. Veneer peeling through machines ensures an efficient processing of logs, is optimal for production of single layers of plywood and is used in coating of fine surfaces or production of block board veneers.

Veneer drying: There are some different methods for drying veneers. In hot and dry area, the most common option is air-drying method, which put the veneers in the sun for the evaporation of water in the veneers, in this way, veneers can be dried to a moisture content of 12-20%, but it cost much more time-about 10-30 days. Another methods which can shorten much time—veneer dryer.

Hot Air veneer dryer is one of the main equipment in plywood production used to dry the veneer with thickness under 1.5mm. It contains front driving frame and back driving frame, drying area and cooling section. The drying area is divided into several sections, and usually each section is 2 meter in length. This machine is customized according to the production capacity.